Machinery

-

CNC steel plate saw and milling machine

Contact UsApplicable to general steel, stainless steel, die steel, alloy structural steel, spring steel, wear-resistant steel and other materials, using efficient and accurate “sawing instead of milling” to replace the traditional cutting and fine milling process. Tungsten carbide circular saw blades are thinner, with less consumables and can reduce tool wear and thus reduce power consumption. The sturdy shockproof design increases cutting speed and extends the life of the saw blade.

-

CNC320 CNC EDM Sinker Machine

Contact UsAdaptive discharge machining process.

High speed lifting and lifting tool height control.

Spindle fixed point control, discharge gap detection

Groove oil level control.

Fire-proof control, Automatic alarm device.

Carbon deposit prevention function

Automatic measurement.

Precise edge and plane machining

Finish the servo system of

X Y Z, Panasonic AC servo motor.

X Y Z, resolution 0.4um, Minimum drive unit 1um..

Stainless steel edge for wear resistant. -

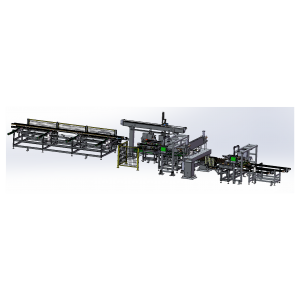

Core Builder for Plate Bar Heat Exchanger

Contact UsFor vacuum brazing Aluminum Plate Bar Cooler, traditional radiator core assembly method is to adopt the width adjustable fixed high baffle on the cast iron platform. After core assembly, professional person has core trimming and use heavy stainless cast steel clamps and long bolts, nuts to fix core. This method is time-consuming and labor-intensive, and cannot make full use of the heating space of Vacuum Brazing Furnace.

-

Custom Fin Forming Machine and Fin Molds

Contact UsFins are the basic components of heat exchanger, on which heat transfer to be finished depends. Main fin types: offset fin, straight fin, perforated fin, louvered fin, corrugated fin. High Speed Automatic Fin Forming Machine and Fin Molds is the special equipment to produce all kinds of Heat Exchanger Fins. With different fin molds, Heat Exchanger Fin production machine can automatically and stably produce all kinds of aluminum fins, Copper Fins and SS Fins.